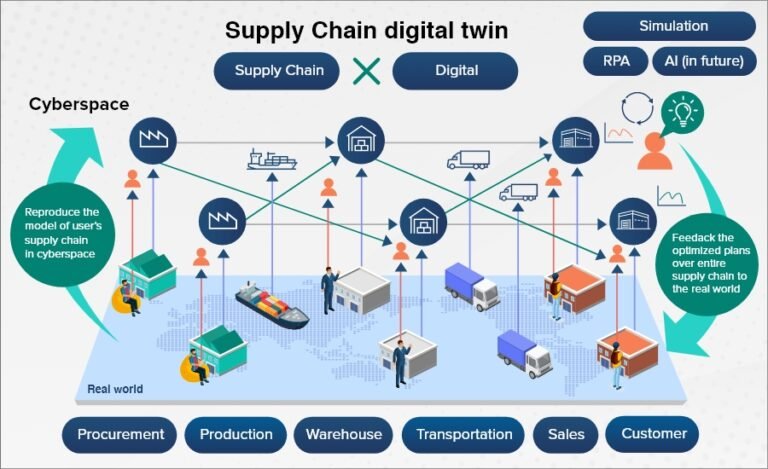

Supply chain optimization using predictive modeling is transforming the logistics industry, making operations more efficient and cost-effective. Companies are leveraging AI in supply chain management and machine learning for supply chain optimization to predict demand, manage inventory, and reduce disruptions. With data-driven supply chain strategies, businesses can enhance decision-making, minimize risks, and improve overall efficiency. This blog explores how predictive analytics and AI are revolutionizing supply chain processes.

Supply Chain Optimization Using Predictive Modeling

Predictive modeling helps businesses forecast demand, optimize inventory, and streamline logistics. By analyzing historical data and market trends, companies can predict seasonal fluctuations, supplier performance, and transportation delays.

For example, retailers use predictive analytics to ensure they stock the right products at the right time, reducing overstocking and shortages. This data-driven approach improves efficiency, lowers costs, and enhances customer satisfaction.

Improving Supply Chain Efficiency Through Predictive Analytics

Predictive analytics plays a crucial role in improving supply chain efficiency. By analyzing large datasets, businesses can identify inefficiencies, reduce lead times, and enhance production planning.

- Demand Forecasting: AI-powered tools predict future demand trends, allowing companies to adjust production accordingly.

- Real-time Inventory Management: Businesses use predictive analytics to monitor stock levels, preventing overproduction or shortages.

- Optimized Delivery Routes: Logistics companies analyze traffic patterns and weather conditions to optimize delivery schedules.

This proactive approach minimizes waste, delays, and operational costs, making supply chain processes more resilient and agile.

AI in Supply Chain Management: Transforming Decision-Making

AI-driven technologies are revolutionizing supply chain management by automating processes, improving accuracy, and enhancing efficiency. Companies use AI for:

- Supplier Risk Management: AI evaluates supplier reliability based on historical performance and market conditions.

- Automated Warehousing: Robotics and AI-powered inventory systems improve warehouse efficiency.

- Real-time Data Analytics: AI processes large volumes of data to provide actionable insights.

For example, Amazon’s AI-driven fulfillment centers optimize inventory distribution and delivery speed, setting a benchmark for supply chain efficiency.

Machine Learning for Supply Chain Optimization

Machine learning for supply chain optimization enhances decision-making by continuously learning from data. It helps businesses:

- Detect Anomalies: Identify unexpected supply chain disruptions before they escalate.

- Enhance Demand Planning: Predict consumer buying patterns with high accuracy.

- Reduce Costs: Optimize shipping routes, labor allocation, and inventory levels.

Machine learning models improve over time, making supply chains smarter and more adaptive to changing market conditions.

Data-Driven Supply Chain Strategies for Competitive Advantage

Data-driven supply chain strategies enable companies to move from reactive to proactive decision-making. By integrating big data, IoT, and AI, businesses gain real-time visibility into supply chain operations.

- Blockchain for Transparency: Enhances traceability and fraud prevention in supply chains.

- IoT-Enabled Sensors: Provide real-time monitoring of shipments and warehouse conditions.

- Advanced Analytics Dashboards: Offer insights into supplier performance, logistics, and demand fluctuations.

These strategies ensure that businesses stay competitive, reduce risks, and enhance supply chain resilience.

Conclusion

The integration of AI, machine learning, and predictive analytics is revolutionizing supply chain management. Supply chain optimization using predictive modeling helps businesses forecast demand, reduce inefficiencies, and improve decision-making. Companies leveraging data-driven supply chain strategies are seeing enhanced productivity, reduced costs, and improved customer satisfaction.

By adopting AI-powered tools, businesses can create smarter, more efficient supply chains that adapt to ever-changing market demands. Are you ready to optimize your supply chain with predictive analytics?